Few people realize that shopping for a replacement bar or chain for your chainsaw requires you to expand your vocabulary.

Trying to measure a new chain? You’ll need to know not only the number of drive links the old chain had but also the old chains' pitch (the distance between the drive links) and the gauge (the width of its bar groove). What about a new bar? You’ll need to know the maximum called length (the useable length of the bar between the saw's body and the bar's tip) your saw can handle.

Even if you’re familiar with those measurement terms, you might see other words that describe the various kinds or styles of chains and bars available and not know what they mean.

This guide doesn’t discuss the terms like pitch and gauge that you need to know to size your chain; our Bar and Chain Sizing Guide has that information.

However, if you’d like an overview of different types of specialty chains, cutters, and tips as well as a quick look at different types of bars, you’re in the right place.

Types of Specialty Chains

Over the years, new types of chainsaw chains have been designed to make cutting faster and easier or to better suit a specific job. You’ll find three types of specialty chains commonly available:

- Low profile chain

- Narrow kerf chain

- Ripping chain

Low Profile Chainsaw Chain

Low profile or “lo pro” chain uses cutters that aren’t as tall as the cutters on standard chainsaw chain. This means that low profile chain makes a shallow cut.

The advantage of using low profile chain is that it weighs less than standard chain, which makes it a good fit for low-horsepower saws and electric saws. The lighter weight of the chain places less strain on the engine.

Low profile chain is generally available in a 3/8” pitch and a .050” gauge and fits bars specifically made for low profile chain. If your saw uses a bar that requires more than 72 drive links on its chain, low profile chain will not work with your bar and saw.

Narrow Kerf Chain

Just as low profile chain has shorter cutters than standard chain, narrow kerf chain has narrower cutters than standard chain. The result of using narrow kerf chain is a thinner, narrower cut.

Because the cuts are thinner, narrow kerf chain ultimately removes less wood than standard chain when cutting. However, this also allows your saw to cut more quickly and to use a long bar with a full-size chain even with a low-horsepower saw. Narrow kerf chain is often an excellent choice for electric chainsaws.

Always check the compatibility of your narrow kerf chain with your bar and your saw. Your bar must be designated as a bar designed to fit narrow kerf chain.

Like low profile chain, narrow kerf chain might be available under a brand name such as Husqvarna’s Pixel chain. Some narrow kerf chains are also low profile chains to offer the ultimate lightweight, high-speed cutting experience.

Ripping Chain

Both low profile chain and narrow kerf chain can help you use your chainsaw more efficiently for standard tasks: pruning tree limbs, cutting branches into smaller logs, and so on.

In contrast, ripping chain is designed for a specific task: milling logs into planks of wood.

The cutters on ripping chain cut at a lower angle than those on standard chainsaw chain – 10 degrees versus the standard 30 degrees. Ripping chain also cuts along the wood’s grain instead of against it.

As a result, ripping chain removes smaller chunks of wood and is less aggressive, despite what its name suggests. This makes it better for creating fine cuts and smooth planks and helps explain its higher price.

If you plan on using a portable sawmill with your chainsaw to mill lumber, ripping chain will be an essential investment.

Types of Cutters

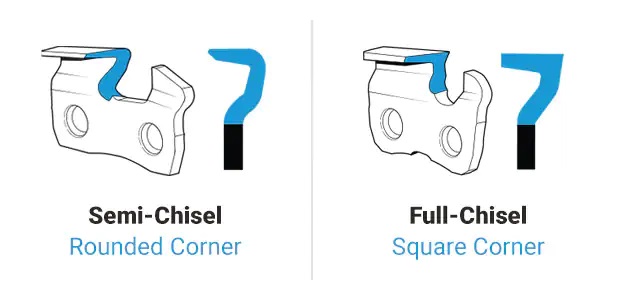

Not only can you find different types of chainsaw chains; you can also find different types of cutters on chainsaw chains. This issue becomes most important when studying the differences between full chisel and semi chisel chain.

Full chisel chainsaw chain has squared, sharply pointed cutters that cut wood aggressively. They allow the chain to move through wood quickly, which is why full chisel chain often is considered the best professional chainsaw chain.

The cutters on semi chisel chainsaw chain, however, are rounded. Their cutting edges dull more slowly when exposed to dirt and debris. Because semi chisel chain is so forgiving of rough conditions, it’s often considered a good homeowner chainsaw chain.

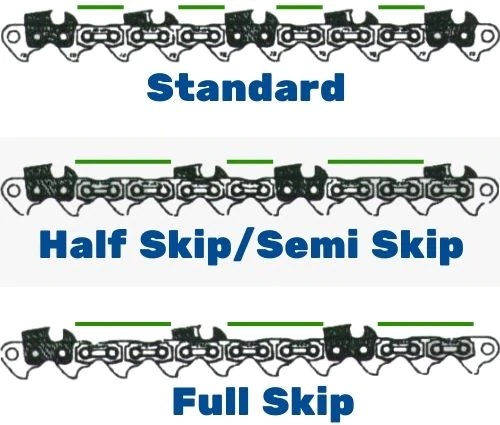

Additionally, you almost might see full skip and semi skip chain available. Both styles of chain have fewer cutters than standard chain; semi skip chain has more cutters than full skip chain.

With fewer cutters tearing through the wood, full-skip and semi-skip chain experience less drag and can cut quickly. They work well with low-power saws or saws with extremely long bars. They also require less time to sharpen.

Types of Chain Cutter Tips

It isn’t just the shape of the cutters or the number of cutters on a chain that determines how well the chain cuts. Cutting ability also depends on the material found at the cutters’ edges or tips:

- Chrome

- Carbide

- Diamond

Both full chisel and semi chisel chain have chrome-tipped cutters. Dipping the cutting edges in chrome helps keep them sharp and resistant to debris.

owever, cutters with chrome tips are considered standard. Even more durable than standard chain is carbide-tip chainsaw chain.

Carbide tips last longer than chrome and are not affected by heat. Because of these qualities, carbide chain is excellent for cutting objects that would dull standard chain quickly, such as railroad ties.

Carbide-tipped chain is also recommended for professionals working in emergency situations:

- Cutting through walls and roofs

- Cutting through icy wood in frozen water

- Cutting through waterlogged wood in frozen rivers

Carbide chain may be more expensive both to purchase and to sharpen, but as a professional chainsaw chain, its durability and sharpness make it invaluable.

More expensive than carbide chain is diamond-tipped chain. You likely won’t have to worry about paying for this upgrade while working in the woods, though. Diamond chain is made to cut rocks and concrete and should be used only with bars and saws designed for that purpose.

Types of Chainsaw Blades or Bars

You might find that some manufacturers’ replacement bars have distinct special features. Oregon's Intenz bars, for example, let you correctly tension your chain simply by loosening the bar nuts and turning a screwdriver in the chain adjustment slot. Certain manufacturers have designed some models of their saws to work only with Intenz bars.

However, there are a couple of distinctions among other types of bars that apply across all makes and models besides Intenz bars:

- The differences between solid and laminated bars

- The differences between hard nose bars and replacement sprocket nose bars

Solid vs. Laminated Chainsaw Bars

Whereas solid bars are made from one solid piece of steel, laminated bars are made by joining two steel rails with a steel core and a sprocket between them. What solid bars offer in sheer strength, laminated bars offer in higher flexibility.

The decision is yours as to which quality – strength or flexibility – is more important. However, keep in mind that the longest laminated chainsaw bars you’ll find will be 24” long.

Hard Nose vs. Replaceable Sprocket Nose Bars

Solid bars can be divided further into two additional sub-categories: hard nose bars and bars with replaceable sprocket noses.

replaceable sprocket nose bars are the standard. These bars feature a sprocket at the tip or nose of the bar with rivets on which the chain sits. By holding the chain securely in place, the rivets help it turn smoothly. Additionally, although the majority of the bar is solid metal, the nose of the bar can be separated and replaced in case of damage.

In contrast, hard nose bars are exactly what you expect a solid bar to be: one piece of metal that's solid all the way through, even through the nose. These sturdy bars are excellent for dirty conditions and for jobs such as sawing fence posts that require you to use the nose to bore directly into the wood.

Why Differences Matter

When buying your new bar and chain, you might be tempted simply to buy the fastest, strongest, most expensive parts available. But don’t pay more than necessary for the wrong type of bar or chain.

Instead, think about the size of your saw and the power with which it operates. Consider the type of work you plan to do with it – will you be using your saw for some light pruning around the yard or for heavy-duty professional work?

With those questions in mind and a solid understanding of bar and chain terminology, you can define exactly what you need for your chainsaw.